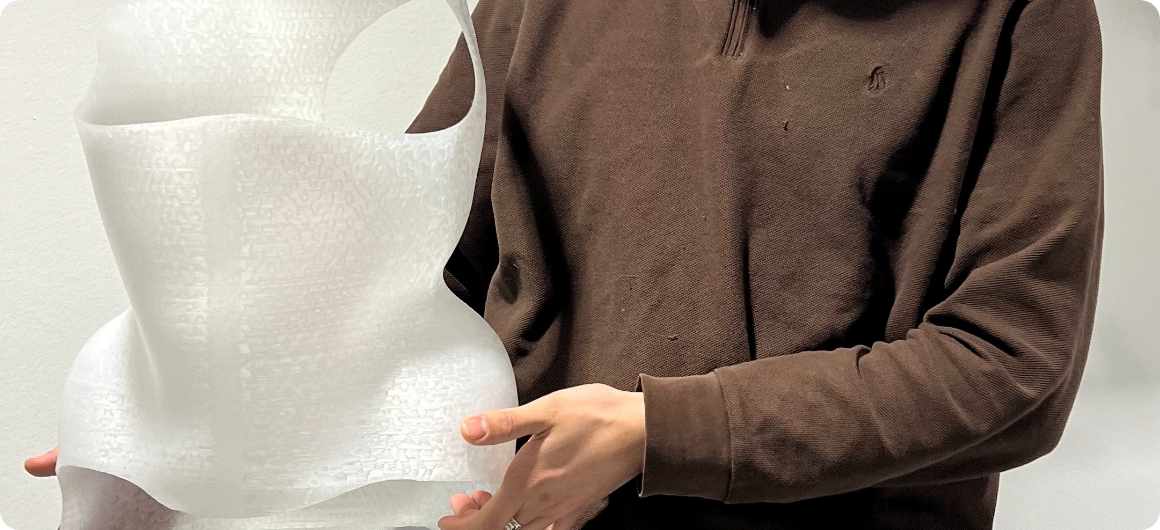

Gets you moving

About us

Shapemakers

Founded in 2012 as ‘OrthoShapes,’ Shapemakers has always been dedicated to the digitalization and optimization of processes in the creation of orthoses and prostheses. In the past years, it became increasingly clear that not all activities fell under the orthopedic market. For this reason, during its 10th-anniversary celebration, OrthoShapes decided to change its name to Shapemakers. Under this new name, we hope to become even more accessible to all the markets we operate in, namely orthopedics, sport en industry.

News

Stay tuned

Shapemakers

Contact

Discussing possibilities

To place an order with us, you need to have an organization account. Would you like to order orthopedic molds and/or 3D prints? We have our own order portal for our customers, where you can place orders and track their status.

Don’t have an account yet? Please contact us to gain access to the order portal.

nl

nl de

de